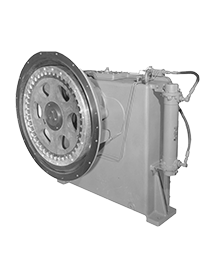

High-performance gearboxes. Collaborative team of experts.

Cotta Engineered Gearboxes are the most reliable and powerful products available in our industry. We take great pride in designing each unique gearbox with the latest technology. We deliver the best possible high-speed gearbox, speed increaser or reducer, pump drive, transfer case, or product type your situation requires.

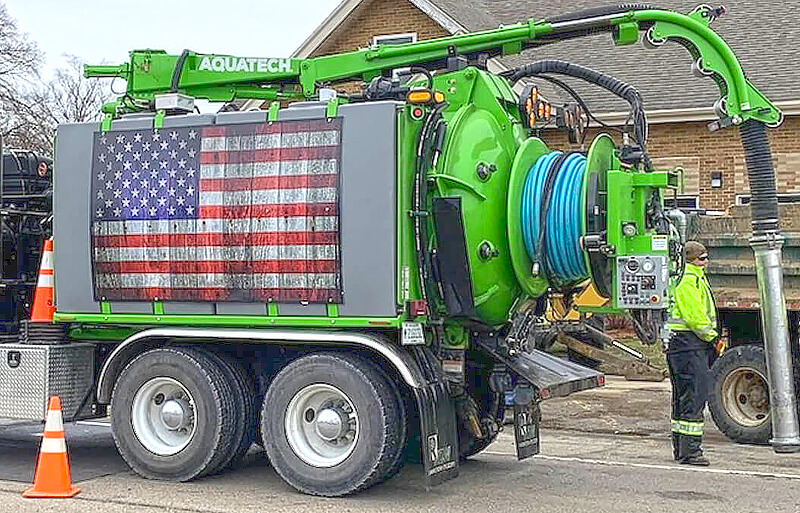

Proudly Made in the USA